Hi all,

I am about to dismantle, overhaul and reassemble on the gear box shaft the clutch of a B22 500cc sidevalve belonging to an associate of mine. The clutch assembly became detached from the gearbox shaft during use without apparent damage occurring to the threaded end of the shaft or the clutch housing itself. I am seeking advice from anyone who knows the innards and workings of the clutch sufficiently well to advise on the procedure of overhaul and reassembly and who may be able to pass on any tips and/or warnings about pitfalls that they have learnt about along the way.

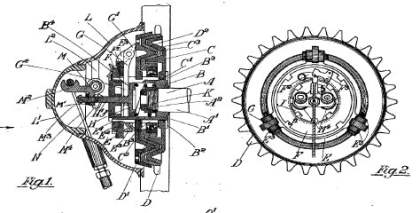

The clutch is stamped 'Patent No. 127099/18' of which I have a copy including the sketches one of which is included among the images below. This sketch indicates friction discs with multi conical shaped grooves which I doubt exists in the clutch at hand - rather I believe it to have flat friction plates, probably as a result of design modification at a time between the patent date of 1918 and the bike production in 1922. The clutch operating mechanism and cable position is also different to that shown on the sketch but that's incidental and not expected to pose any great problem.

If the clutch linings need replacing specifically what material in what thickness might be required? What clearance should be allowed between clutch engagement and disengagement - I guess just enough to allow minimum or no friction on disengagement? Has anyone a parts list or manual notes for this type of clutch that they would be prepared to post here or email to me?

Any help at all will be appreciated.

Alwyn.

The clutch assembly...

Larger view

Larger view Larger view

Larger view Larger view

Larger viewDrawing from patent document...